ESSENTIAL CONCEPTS

Five key components constitute a passive house. We will discuss them here briefly and urge those who want to know more to visit the Passive House International (PHI) website. We will not go deeply into data here, but rather try to present the idea in simple language.

The five are:

- Air-tight building envelope

- Super-insulation

- Thermal-bridge-free construction

- High-efficiency windows and doors

- Mechanical ventilation with heat-recovery (HRV or ERV)

AIR-TIGHT BUILDING ENVELOPES

are often misunderstood.

No, you will not suffocate. In fact, a proper passive envelope with mechanical ventilation supplies more than ample fresh air and far more than in traditionally constructed homes.

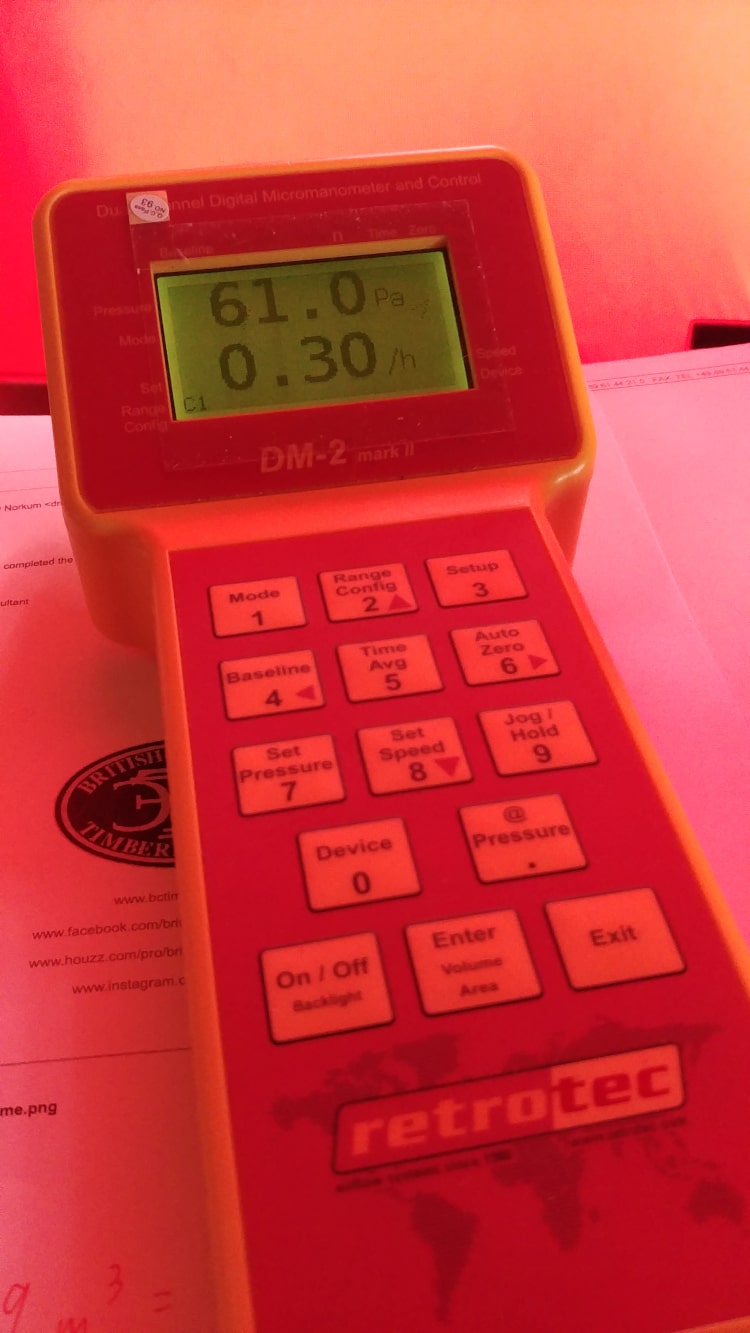

The metric for air-tightness is called ACH, air changes per hour. This is gauged using a blower-door test, which is a common thing in construction today and is in fact mandated for all new residential buildings under British Columbia’s “step code” towards net-zero homes. With a blower door the building is pressurized and then air leakage is measured electronically. The passive house target for ACH is 0.60, meaning that .60 of the volume of the air in the house would leak out in an hour under 50 kPa (kilo pascals) of pressure. Our McDonald passive house on completion achieved 0.35 ACH, an excellent result.

The passive house ACH is more stringent than any other building standard. In time, building codes will approach that 0.60 number but are likely to be less demanding. When adopted, the “Step 5” in British Columbia will demand 1.0 ACH.

SUPER-INSULATION

keeping the outside, outside

Passive houses, regardless of wall build-up, have very thick walls. McDonald passive house’s walls are 35 cms (14 inches) and that includes a 25 cm wall panel plus a 10 cm “service cavity” where plumbing and wiring go. The wall panels are filled with “Jet Stream” insulation made with post-consumer glass. The service cavity contains Rockwool. Very importantly, all seams are taped to prevent air leakage.

Key to passive house is that insulation is continuous, that is, there are no breaks that will allow for thermal bridging.

THERMAL BRIDGE FREE

heat seeks cold. We have top stop it.

A law of physics (thermo dynamics) is that heat wants to go where it is cooler. Heat seeks “bridges” where it can escape, and those bridges must be prevented in passive-house building. Material selection is of paramount importance because different types of materials have different conductive properties. Even wood will conduct heat. Avoiding any bridging contributes to the continuous insulation mentioned above.

HIGH EFFICIENCY WINDOWS AND DOORS

triple-glazing and rock-solid seals

Passive houses are triple-glazed and their window frames and doors are designed to minimize thermal bridges. Our McDonald project used windows made by M Sora of Slovenia. Passive House Institute-certified windows and doors are now available worldwide, and there are some North American producers of excellent windows. The gold standard has traditionally been windows from Austria, but the expense of these windows is not necessary. One needs to focus on the performance of the window, and not so much the manufacturer. Any good window-maker will have performance statistics available – ask for them.

Remember that a window leaks heat through its frame more than through the glass. For this reason, good window-makers focus on isolating thermal bridges in frame design. The European-standard tilt-and-turn window is by far the best as they seal effectively and are thus air tight.

MECHANICAL VENTILATION

The lungs of your passive house

As we have discussed, heat-recovery ventilation (HRV) is key to passive house. Using heat-exchangers, they allow air to move between the inside and outside without the energy leaving the building. Simply put, the exhaust air leaving the house warms the air that is coming in. Heat exchangers are nothing new: they have always been used in industrial applications where energy-efficiency saves money. They do the same for the home, although we have been slow to adopt them. Luckily, HRV (and ERV, or energy recovery ventilation) is now commonplace. The level of efficiency of HRV units varies widely, however. Again, the European HRVs are the standard, with those made by Germany’s Zehnder being the best, recovering over 90% of heat in exhaust air. Other makers of HRVs in North America, Japan and China are rapidly coming up the curve and bringing down the cost of heat recovery as a result.

Using an HRV not only saves energy, but makes a comfortable and healthy indoor environment (most also Hepa-filter the air as it enters the building). You immediately notice the quality of the indoor environment in a passive house.